Double Head Welding Machine

➢ Used for upvc window door corner welding.

➢ Plc control the machine working.

➢ Left head is fixed ,right head can moveable on linear guide rail.

➢ Two machine head can work separately or linkage.

➢ Linear guidway features more precise.

➢ Weld two point, single point, transom, cross -transom and special angle.

➢ Various angles welding between 30 to 180 degree is available on last machine head.

➢ Pneumatic drive, simple operation, stable capability.

➢ Solid machinery base and structure ensure long life service with high dimension accuracy.

| Power supply |

220V,50-60Hz, Single Phase |

| Input power |

2.5kw |

| Spindle rotary speed |

2800r/min |

| Air pressure |

0.4~0.6Mpa |

| Air comsumption |

100L/min |

| Welding height |

25~120mm ,Max. 180mm |

| Welding width |

120mm |

| Welding range |

400~3500mm |

| Overall dimension |

4400*1100*1700(L*W*H) |

| Heating plate |

2pcs |

| Mobile work pieces supports |

1set |

| Teflon Cloth(welding cloth) |

Several |

| Complete tooling |

1set |

| Certificate |

1pcs |

| Operation manual |

1pcs |

| PLC |

Mitsubishi, TCD |

| Solenoid valve |

Airtac |

| Cylinder |

Best & Huatong Shandong |

| Air filter device |

Airtac |

| Electric button & knob switch |

Schneider |

| AC contactor & MCB |

Renmin Shanghai |

| Temperature Controller Meter |

Chuanglida |

| Any angle welding block Extra welding cloth Max. Welding height (180mm ,especially for some of 3 track sliding door frame system) |

Common type two head welding machine with heavy duty body and inside electric control box( It can avoid damage during transport)

Machine head adopts casting parts with high quality

Equipped with heavy material clamping plate and moveable block.

Customer can change block as per requirements.

All the machine packed with standard export wooden case to make sure customer will received the machines they ordered intact.

All the machines & accessories can be shipped worldwide by sea, by air or by international courier via DHL, FEDEX, UPS.

Packing Detail:

➢ Inner package: stretch film

➢ Outside package: standard export wooden cases

Delivery Detail:

➢ Usually we will arrange dispatch within 3-5 working day after receive payment.

➢ If there are big order or customized machines, it will take 10-15 working day.

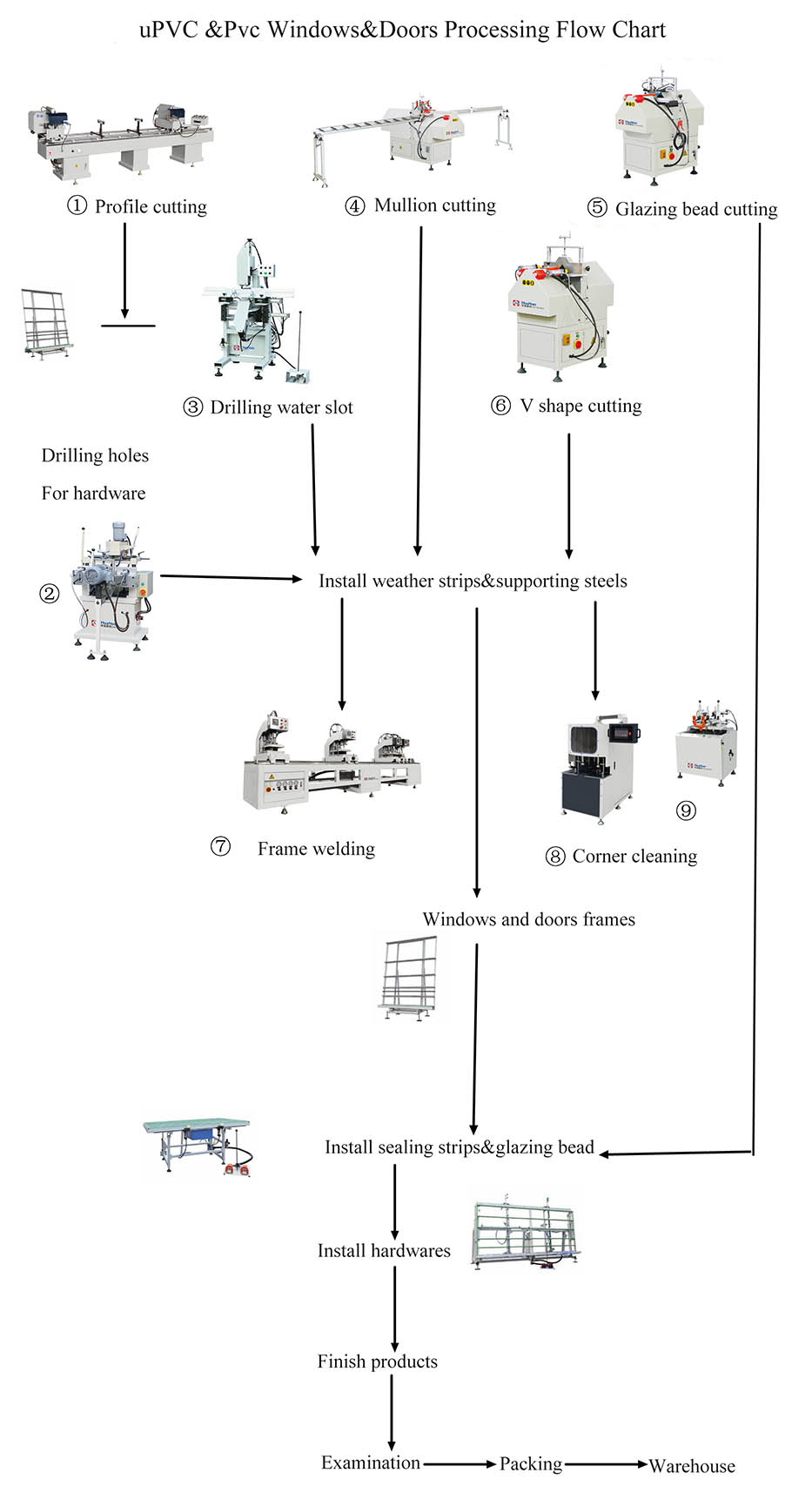

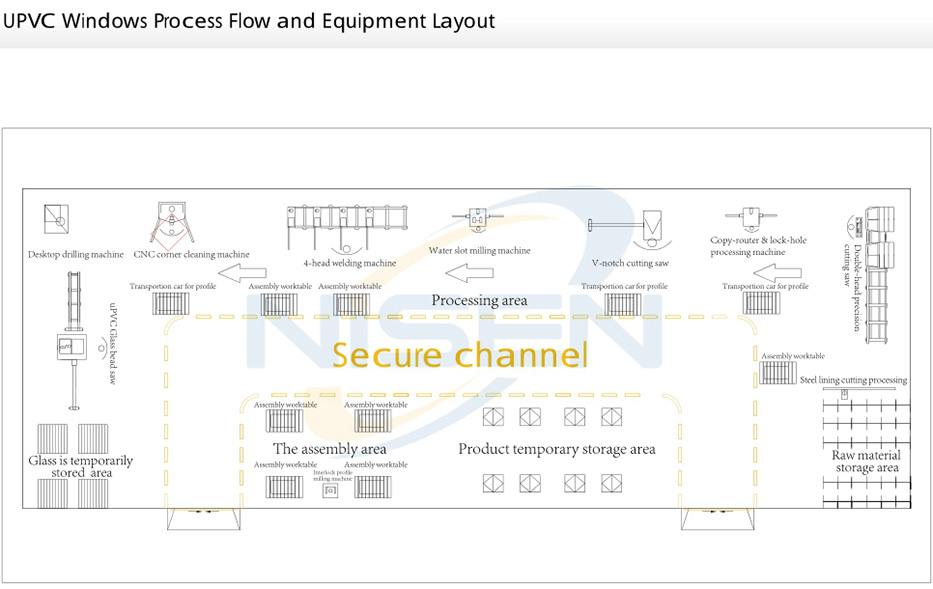

➢ We will according to customer's requirements (budget, plant area etc ), to provide the best solution for customers.

➢ All project report and factory layout arrangement are available for valuable customer.

Machine maintenance is necessary, it will helpful for your machine life, please clean all dusty after use the machine. Frequently check the PLC or the following:

6.1 Check to see if there is anything giving out excess heat or if the sun is shining directly on the machine, which can make the temperature in the controller rise, too high.

6.2 Check if there is some electric dust getting in the.

6.3 Check the arrangement of wires and the terminals to see if they are loose or damaged.