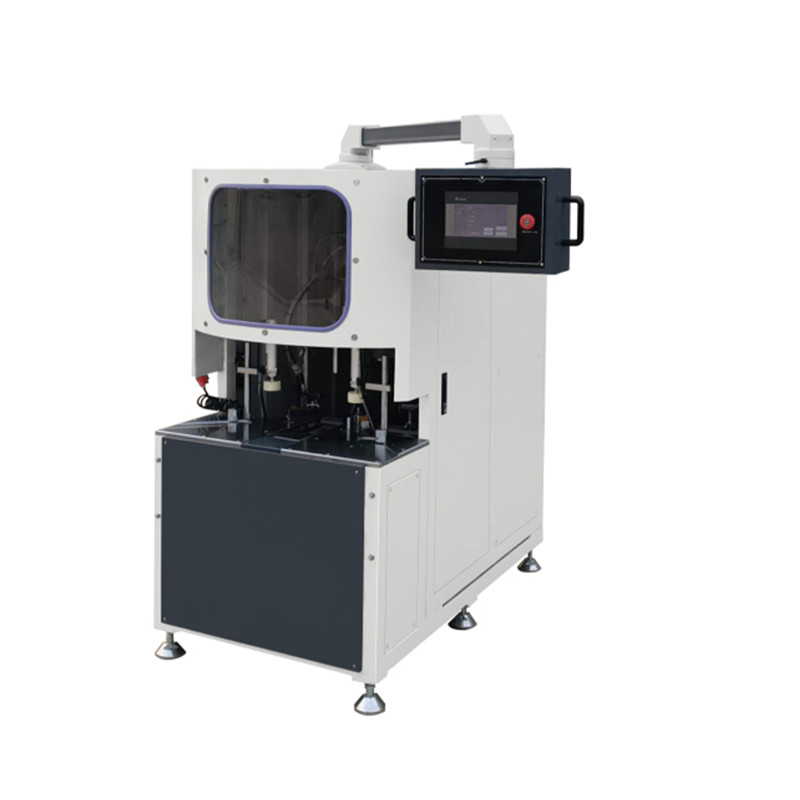

PVC Profiles CNC Corner Cleaning Machine For Windows And Doors

➢ Used for cleaning the up/bottom surface and the external corner.

➢ High processing precision due to size error compensation function.

➢ Famous brand of servo-drive system, CNC system , solenoid valve, air treatment unit and so on ensure reliable performance and long using life.

➢ Can store 100+ programs for different profiles processing.

➢ Within 25 seconds finish one corner complete cleaning.

➢ Can be linked with horizontal welding machine to become welding & corner cleaning production line for grand imagine and high efficiency.

➢ Specially equipped with power-off protection function.

| Power supply |

380v 50-60Hz, three phase |

| Input power |

1.5kw |

| Air pressure |

0.4~0.7Mpa |

| Air comsumption |

80L/min |

| Profile height |

20~120mm |

| Profile width |

20~100mm |

| Drawing groove width |

3mm |

| Drawing groove depth |

0.3mm |

| Overall dimension |

1600*880*1650(L*W*H) |

| Blades | 2pcs |

| Air gun | 1pcs |

| Complete tooling | 1set |

| Certificate | 1pcs |

| Operation manual | 1pcs |

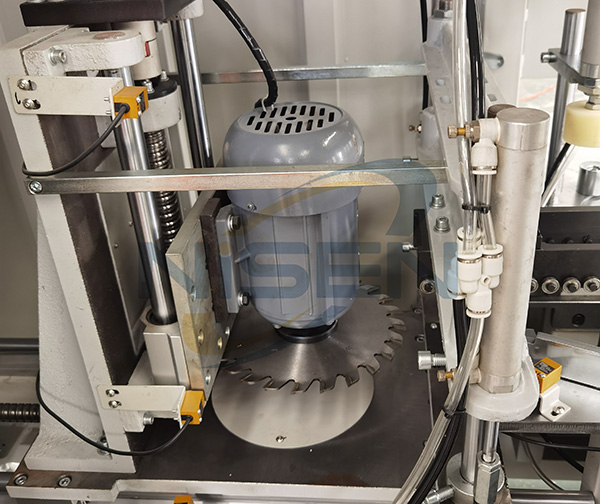

For 4 cutters cleaning machine, it can cleaning top & bottom surface, outside corner and internal cavity of the upvc profile windows doors.

For 3 cutters CNC cleaning machine, it can cleaning top & bottom surface, outside corner of the upvc profile windows doors only.

The machine adopts the latest structure, in order to ensure the accuracy of the machine, and also with reasonable layout.

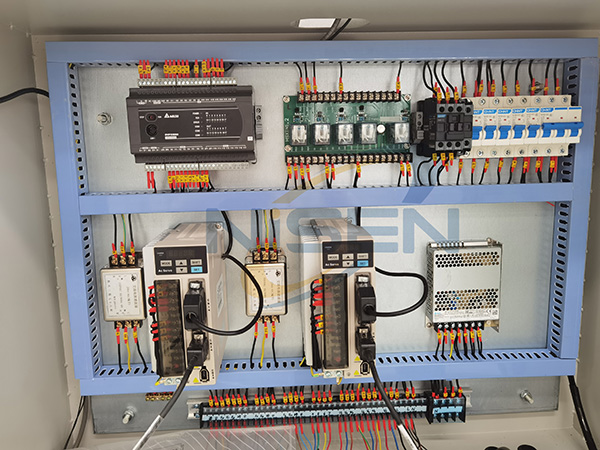

The orderly and reasonable line arrangement ensures the stability of the circuit with high-quality components.

And the machine is equipped with voltage regulator.

All the machine packed with standard export wooden case to make sure customer will received the machines they ordered intact.

All the machines & accessories can be shipped worldwide by sea, by air or by international courier via DHL, FEDEX, UPS.

Packing Detail:

➢ Inner package: stretch film

➢ Outside package: standard export wooden cases

Delivery Detail:

➢ Usually we will arrange dispatch within 3-5 working day after receive payment.

➢ If there are big order or customized machines, it will take 10-15 working day.

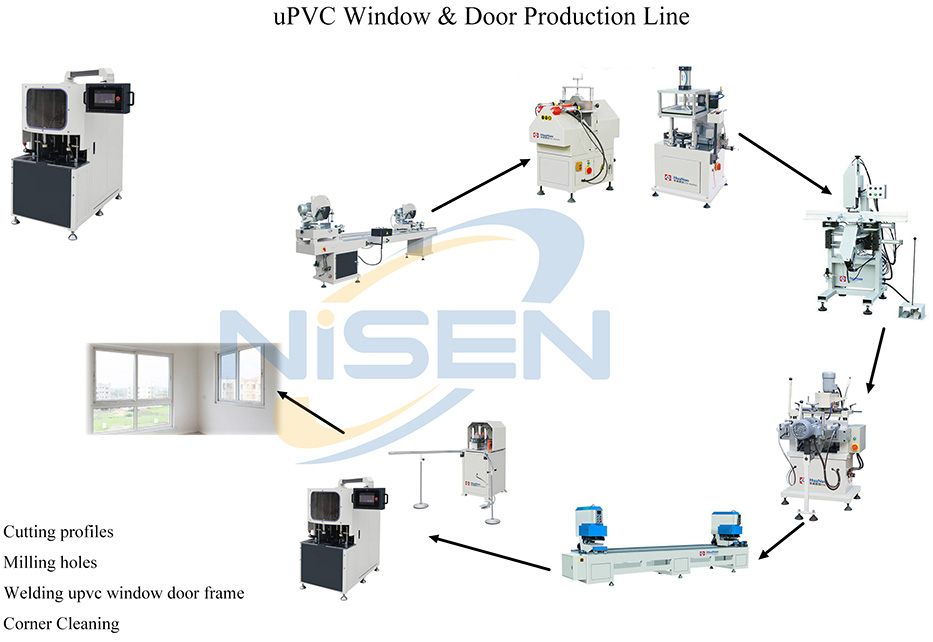

We will according to customer's requirements (budget, plant area etc ), to provide the best solution for customers.

All project report and factory layout arrangement are available for valuable customer.

Machine maintenance is necessary, it will helpful for your machine life, please clean all dusty after use the machine.

7.1 Lubricating

Lubricating oil need add on the machine part (milling cutter bearing, Y-axis ball screw and its nut, x, y axis shaft and guide rail etc.)

7.2 Check and change the cleaning blades as usual.