Two Axis Water Slot Milling Machine for UPVC Window Door Machinery

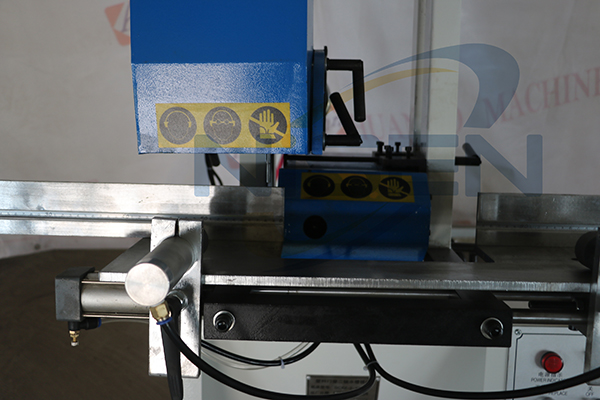

➢ Used for milling all kinds of water slots and air pressure balance grooves on windows and doors.

➢ Adjustment of the angle and height of milling for different profile types.

➢ The length of milling water slot within 60mm is adjustable and its usage range is wide.

➢ Each milling head can work together and independently.

➢ Pneumatic clamping system ensure stable and accurate processing profiles.

➢ Adopt linear bearing motion to ensure the processing precision.

| Power supply |

380V,50-60Hz, Three Phase |

| Input power |

2*0.38kw |

| Spindle rotary speed |

25000r/min |

| Air pressure |

0.5~0.8Mpa |

| Air comsumption |

15L/min |

| Drilling bit diameter |

Φ5mm φ4mm |

| Slot depth |

30mm |

| Slot length |

30*60mm |

| Overall dimension |

1925*750*1600(L*W*H) |

| Drilling bits |

2pcs |

| Mobile work pieces supports |

1set |

| Air gun |

1pcs |

| Complete tooling |

1set |

| Certificate |

1pcs |

| Operation manual |

1pcs |

| Drilling bit |

Weike |

| Solenoid valve |

Puteer |

| Cylinder |

Best & Huatong Shandong |

| Air filter device |

Puteer |

| Electric button & knob switch |

Schneider |

| AC contactor & MCB |

Renmin Shanghai |

Water slot milling machine adjusts the processing range by hand wheel, which is convenient and simple.

Water slot milling machine can processing profile using 2 axis to complete processing of water slots and pneumatic balance holes, with high efficiency.

Two axis water slot milling machine can packed by single wooden case and delivery by LCL shipping ,for one machine, at least 5 days will finish production.

For packing, firstly inside will pack stretch film, after that will arrange wooden case as per customer requirements.

Packing Detail:

➢ Inner package: stretch film

➢ Outside package: standard export wooden cases

Delivery Detail:

➢ Usually we will arrange dispatch within 3-5 working day after receive payment.

➢ If there are big order or customized machines, it will take 10-15 working day.

Machine maintenance is necessary, it will helpful for your machine life, please clean all dusty after use the machine.

Drilling bits: please change the drilling bits as soon as you find the drilling bit damaged.

Lubrication: please add oil to lubricate water slot milling machine.

Air filter device: please clean the water-separating gas filter termly and make sure that the oil sprayer has enough oil.

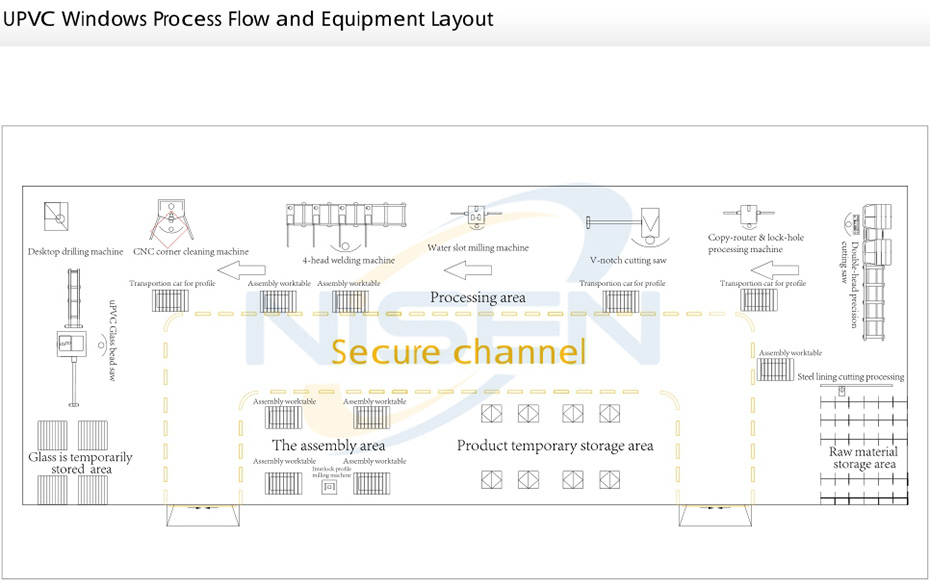

We will according to customer's requirements (budget,plant area etc ), to provide the best solution for customers.

All project report and factory layout arrangement are available for valuable customer.