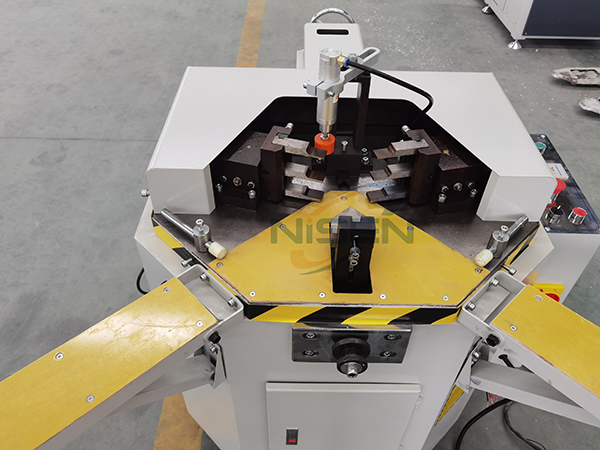

Aluminum Window Door Fabrication Machine for Corner Crimping

➢ Used for assembly of aluminium window and door.

➢ Connecting the corners of two aluminium profiles with a wedge placed inside by applying pressure.

➢ The synchro feeding structure makes the adjustment very easy.

➢ Adopt a new mechanical linkage device, realized complete synchronous corner combing.

➢ It is a collocated single cutter of many points crimping cutter to ensure reliably crimping heat insulation aluminum win-door.

| Power supply |

380V,50-60Hz, Three Phase |

| Input power |

2.2kw |

| Rated oil pump pressure |

16Mpa |

| Capability of oil box |

30L |

| Air pressure |

0.5~0.8Mpa |

| Profile processing height |

Max 180mm |

| Profile processing width |

100mm |

| Corner crimping casing movement journey |

0~100mm |

| General pressure of corner combining |

48KN |

| Overall dimension |

2000*1180*1200(L*W*H)mm |

| Standard Crimping Cutter |

1set |

| Air gun |

1pcs |

| Complete tooling |

1set |

| Certificate |

1pcs |

| Operation manual |

1pcs |

The machine can reach a maximum processing height of 180mm profiles. Suitable for processing curtain wall materials.

The machine is equipped with a separate oil cylinder to ensure the stability of sufficient power and operation.

The rotary adjustment mode is more convenient to use.

Locating device is moveable, easy for take of the profile from the machine.

All the machine packed with standard export wooden case to make sure customer will received the machines they ordered intact.

All the machines & accessories can be shipped worldwide by sea, by air or by international courier via DHL, FEDEX, UPS.

Packing Detail:

➢ Inner package: stretch film

➢ Outside package: standard export wooden cases

Delivery Detail:

➢ Usually we will arrange dispatch within 3-5 working day after receive payment.

➢ If there are big order or customized machines, it will take 10-15 working day.

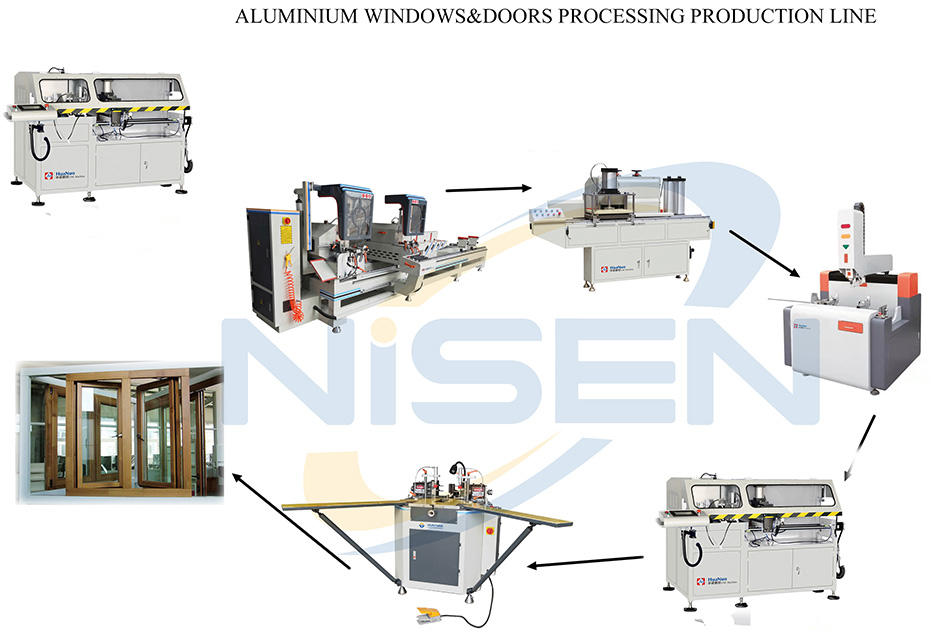

We will according to customer's requirements (budget, plant area etc ), to provide the best solution for customers.

All project report and factory layout arrangement are available for valuable customer.

Machine maintenance is necessary ,it will helpful for your machine life, please clean all dusty after use the machine.

6.1 Liquid level in the tank above the oil standard, to prevent pump cavitation. When refueling, new application 120 mesh screen filter impurities in the oil, oil filter cleaned once every two months, half a tank cleaning, and replace with new oil. After replacing the new oil once a year.

6.2 Normal operating oil temperature 20∽50 ℃, when the oil temperature is too high, need to take measures to cool down or stop the pump until the fluid to cool down, to work; when the oil temperature is too low, not allowed to work directly, to be taken plus Temperature measures can be improved by heating oil or low pressure operation.

Need to be switched off to prevent damage to the gauge 6.5 to work properly.

6.3 Pump should be check and maintenance one year