V Cutting Machine

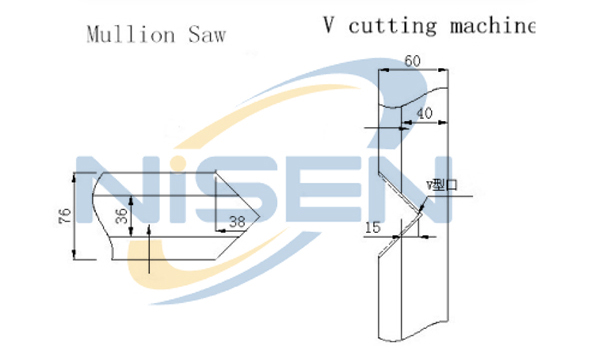

➢ Used for upvc profile V-shaped groove cutting.

➢ Adjustable V-notch depth based on different profile.

➢ Adjustable feeding speed.

➢ Automatic shaping of one pair of saw is cut.

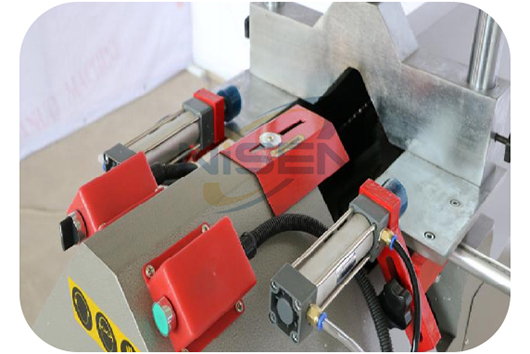

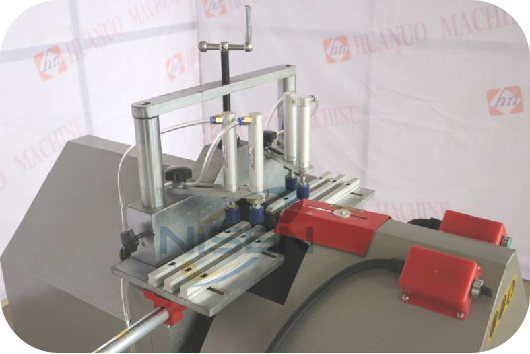

➢ Two saw blade on two separate motor fixed at 45 degree without cross.

➢ Guide rod assist positioning.

➢ Two hand safety operation.

➢ Pneumatic driving, easy operation.

➢ Cutting depth is adjustable.

| Power supply |

380V,50-60Hz,3Ph |

| Input power |

2*0.75kw |

| Spindle rotary speed |

2800r/min |

| Air pressure |

0.4~0.6Mpa |

| Air consumption |

80L/min |

| Depth cutting |

20~60mm |

| Cutting width |

120mm |

| Cutting range |

300~1600mm |

| Saw blade diameter |

Ø300*Ø30mm |

| Overall dimension |

1300*700*1350(L*W*H) |

| Saw blade |

2pcs |

| Mobile work pieces supports |

2pcs |

| Complete tooling |

1sets |

| Certificate |

1pcs |

| Operation manual |

1pcs |

| Saw blade |

Wemero blade (Wagen, Japan optional) |

| Solenoid valve |

Airtac |

| Cylinder |

Best & Huatong Shandong |

| Air filter device |

Airtac |

| Electric button & knob switch |

Schneider |

| AC contactor & MCB |

Renmin Shanghai |

V cutting machine as the important item of making upvc windows and doors.

This machine works on frame profile when making mullion.

There are 2 pcs motors, including to the left and right sides by 45°, to form an angle of 90°. And on each motor, there's 1pcs blade.

They are for different functions. Only similar in appearance and in operating.

How to identify these two machines from appearance?

A: Clamping cylinder:

V-cutting machine has 2 pcs, in horizontal direction

Glazing bead saw has 4 pcs, in vertical direction

V cutting machine

Glazing bead cutting machine

B: Working table:

Glazing bead saw has profile block, can put 2 pcs profiles in the same time

V-cutting machine has no block, directly put profile on working table

C: More details, plz reach at us @admin@huashinuo.com

For v cutting machine, generally, it will pack stretch film and wooden case to make sure customer will receive the machine they ordered intact.

This machine can be shipped by sea or by air, pls drop your port of destination or your address, we will check the shipping cost for you.

Generally, for V cutting machine, we have ready in stock, so it can delivery to you within one week.

Adopting itself to meet market forces, and is maintaining high speed growth within a fierce market of competition.

Our sales network with service support, spread all over India as well as to the international market.

Be keeping & maintaining the strategy of quality, timely delivery, service & customer delight we are one at the trusted and leading supplier of windows & doors machines, insulating glass production line and windows&doors hardware.

Machine maintenance is necessary, it will helpful for your machine life, please clean all dusty after use the machine.

8.1 Air filter device

Adjustment of air filter device (include the water divide and air filter, the manometer, oil sprayer), the filer should be emptied after a work, and be cleaned once a time every week, the manometer should be between 0.4-0.6Mpa. The oil sprayer should be kept over a certain oil quantity (machinery oil 20#), and it should drip a drop every minute.

8.2 Adjustment of the cutting speed

Loosen the locknut of the timing valve on the running cylinder. Turn the roller clockwise to decelerate, counter clockwise to accelerate. After adjusting, tighten the locknut, now the speed should be smooth and without any jumping and creeping.