Double Head Cutting Machine For Upvc Profile

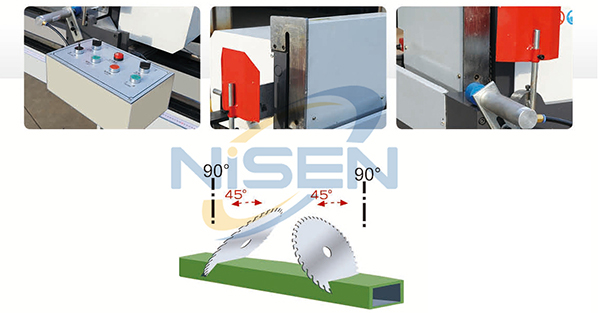

➢ 90°, inside 45, cutting plastic and aluminum profile.

➢ Two saw head can be manually switching angle, realize the -45 degrees, 90 degrees.

➢ Imported carbides blade is of accurate processing and high endurance.

➢ The two heads can work alone, can also work at the same time.

➢ Moveable protecting cover is optional.

➢ The working table moves easy, and can be located in the place where do you need.

➢ Machine bed with three leg, more strong.

| Power supply |

380V,50-60Hz,3Ph |

| Input power |

2*1.5kw |

| Spindle rotary speed |

2800r/min |

| Air pressure |

0.5~0.8Mpa |

| Air consumption |

100L/min |

| Max cutting width |

120mm |

| Saw outside diameter |

Ø400mm |

| Cutting length |

450~3500mm |

| Saw inside diameter |

Ø60mm |

| Saw thickness |

3mm |

| Number of teeth |

120 |

| Overall dimension |

4000*1000*1450(L*W*H) |

| Saw blade |

2pcs |

| Mobile work pieces supports |

2sets |

| Complete tooling |

1sets |

| Certificate |

1pcs |

| Operation manual |

1pcs |

| Saw blade |

Wemero blade (Wagen, Japan optional) |

| Solenoid valve |

Airtac |

| Cylinder |

Best & Huatong Shandong |

| Air filter device |

Airtac |

| Eelctric button & knob switch |

Schneider |

| AC contactor & MCB |

Renmin Shanghai |

| Protecting cover device Digital display device Dust collector system |

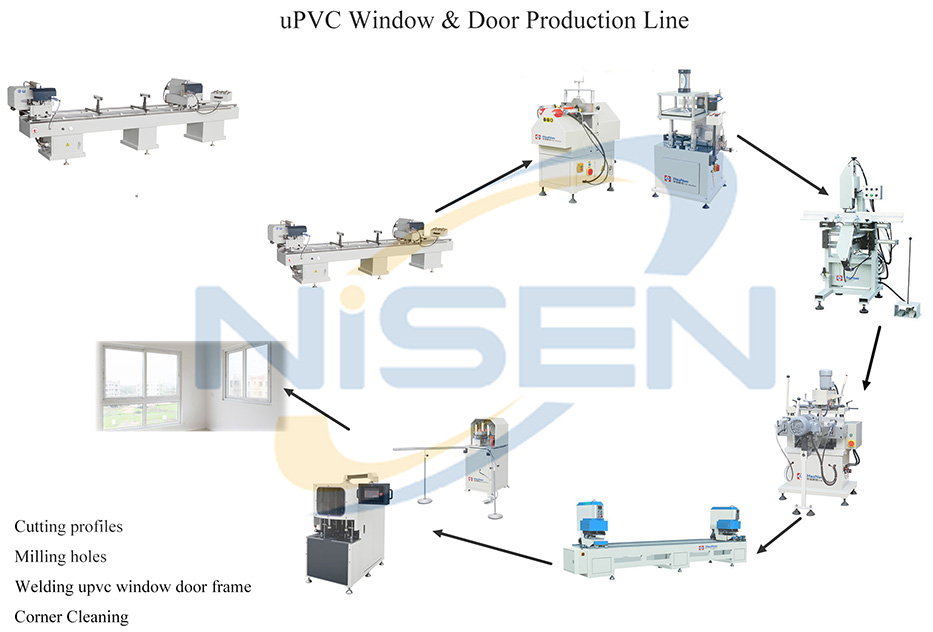

Common double head cutting machine, it can cut upvc profile, also possible to cut aluminum profile.

Digital display system is optional.

Horizontal pneumatic clamping

Saw blade working from backside to front side

45 degree and 90 degree clamping device

For the machine dispatch to your site by safe, fast and effective, we have professional&strict packing requirements. Our worker will packing the machine and check carefully to ensure customer can receive the machine with good conditions.

Packing Detail

For LCL(less container load) shipping, we will adopt the following packing method:

➢ Inner package: stretch film

➢ Outside package: standard export wooden cases

For FCL(full container load) shipping ,all machines will wrap with film and same time fixed the machines into container with steel iron.

Delivery Detail

➢ Usually we will arrange dispatch within 3-5 working day after receive payment.

➢ If there are big order or customized machines, it will take 10-15 working day.

We use the craftsman spirit to do a good job of the product, and are committed to give you the best quality product and services.

Apart from engaged in providing machines & tools and window door hardwares, our company also incluges in offering our clients with efficient & cost effective solutions, which help in the modern industrial requirements of our valuable clients.

The reason behind the success & growth of our company solely depends on the excellent service management accredited by our team members, with vast knowledge & expertise in the respective domain our expects are well aware of all process.

Our engineer can offer you professional factory layout according to your requirements.

Machine maintenance is necessary, it will helpful for your machine life, please clean all dusty after use the machine.

7.1 Lubrication

The bearing of saw head should be time added with lubricating oil.

7.2 Adjustment of the air supply processor (consist of water bifurcation gas filter, manometer, oil atomizer):

The water bifurcation gas filter should be refreshed water every work period and cleaned every week; The manometer is adjusted to 0.4Mpa-0.6Mpa; The oil sprayer should be kept a certain oil level (machinery oil N32) and regulated about a drop every minute.

7.3 Cleaning & change the saw blade regularly

Take down the pole end bearing from U-formed iron.

Take down the fixed protecting shield.

Rotate down the clamping jig of saw blade ,and take down the saw blade.

In the contrary order, install the new saw blade, and add add some oil on the saw blade & inside bearing holes.