Supply ODM China UPVC/PVC Window and Door Plastic Profile Extrusion Machine

We’ve got the most highly developed manufacturing machines, experienced and qualified engineers and workers, acknowledged good quality management systems and also a friendly specialist gross sales team pre/after-sales support for Supply ODM China UPVC/PVC Window and Door Plastic Profile Extrusion Machine, In addition, we would properly tutorial the purchasers about the application techniques to adopt our items plus the way to select appropriate materials.

We’ve got the most highly developed manufacturing machines, experienced and qualified engineers and workers, acknowledged good quality management systems and also a friendly specialist gross sales team pre/after-sales support for China Plastic Machine, Plastic Machinery, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of “innovation, harmony, team work and sharing, trails, pragmatic progress”. Give us a chance and we’ll prove our capability. With your kind help, we believe that we can create a bright future with you together.

Product Description

Feature of upvc window machine

- Used for upvc window door corner welding

- Plc control the machine working

- Left head is fixed ,right head can moveable on linear guide rail.

- Two machine head can work separately or linkage.

- Linear guidway features more precise

- Solid machinery base and structure ensure long life service with high dimension accuracy.

- Weld two point, single point, transom, cross -transom and special angle.

- Pneumatic drive, simple operation, stable capability.

- Various angles welding between 30 to 180 degree is available on last machine head.

|

|

|

220V,50-60Hz, Single Phase |

|

3.5kw |

|

2800r/min |

|

0.4~0.6Mpa |

|

200L/min |

|

25~120mm ,Max. 180mm |

|

120mm |

|

400~3500mm |

|

4300*1100*1700(L*W*H) |

|

|

| 3pcs | |

|

1set |

|

Several |

|

1set |

|

1pcs |

|

1pcs |

|

|

| Mitsubishi ,TCD | |

|

Airtac |

|

Best & Huatong Shandong |

|

Airtac |

|

Schneider |

|

Renmin Shanghai |

|

Chuanglida |

| Optional |

| Any angle welding block |

| Extra welding cloth |

| Max. Welding height (180mm ,especially for some of 3 track sliding door frame system) |

Product details

Packing & Delivery

- All the machine packed with standard export wooden case to make sure customer will received the machines they ordered intact.

- All the machines & accessories can be shipped worldwide by sea, by air or by international courier via DHL, FEDEX, UPS.

Packing Detail:

Inner package :stretch film

Outside package : standard export wooden cases

Delivery Detail:

Usually we will arrange dispatch within 3-5 working day after receive payment .

If there are big order or customized machines ,it will take 10-15 working day .

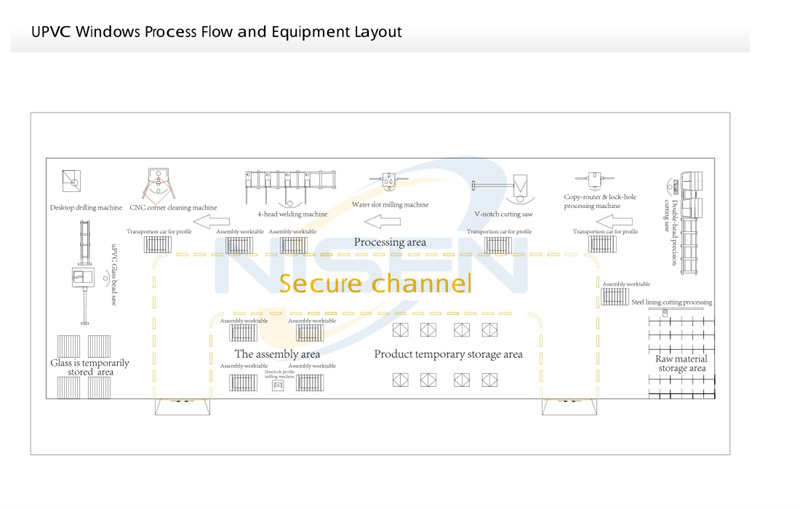

Upvc Window & Door Processing Solution

We will according to customer’s requirements (budget,plant area etc ) , to provide the best solution for customers .

All project report and factory layout arrangement are available for valuable customer.

Machine maintenance

Machine maintenance is necessary ,it will helpful for your machine life , please clean all dusty after use the machine .

7.1 Always check fasteners such as various mechanisms, components, cylinders, etc. to prevent loosening.

7.2 The reference plate and the pressing plate should be kept clean and no upvc profile slags.

7.3 The machine power supply line should be checked every shift; turn off the power and air supply after work.

7.4 The electric control cabinet should be kept clean and dry. Non-professional maintenance personnel should not open the door and circuit.

We’ve got the most highly developed manufacturing machines, experienced and qualified engineers and workers, acknowledged good quality management systems and also a friendly specialist gross sales team pre/after-sales support for Supply ODM China UPVC/PVC Window and Door Plastic Profile Extrusion Machine, In addition, we would properly tutorial the purchasers about the application techniques to adopt our items plus the way to select appropriate materials.

Supply ODM China Plastic Machine, Plastic Machinery, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of “innovation, harmony, team work and sharing, trails, pragmatic progress”. Give us a chance and we’ll prove our capability. With your kind help, we believe that we can create a bright future with you together.