Factory For Aluminum Profile Cutting Machine - Aluminium Corner Connector Profile Cutting Machine – Nisen

Factory For Aluminum Profile Cutting Machine - Aluminium Corner Connector Profile Cutting Machine – Nisen Detail:

Feature of aluminum window machine

➢ Used for cutting aluminum & upvc profile corner key.

➢ High power motor makes cutting more easily.

➢ Linear bearing motion pair give less resistance force and ensured high processing accuracy.

➢ PLC control and auto feeding system, suitable for large volume production.

Technical Specifications

| Power supply |

380V,50-60Hz, Three Phase |

| Input power |

2.2kw |

| Motor rotary speed |

2800r/min |

| Air pressure |

0.5~0.8Mpa |

| Air comsumption |

100L/min |

| Auto feeding length |

5~120mm |

| Cutting width |

120mm |

| Cutting height |

200mm |

| Blade inside diameter |

Φ450mm |

| Blade outside diameter |

Φ30mm |

| Thickness |

4.4mm |

| Number of teeth |

120 |

| Overall dimension |

1240*1300*1300(L*W*H)mm |

Standard Accessory

| Saw blade |

1pcs |

| Air gun |

1pcs |

| Complete tooling |

1set |

| Certificate |

1pcs |

| Operation manual |

1pcs |

Product Details

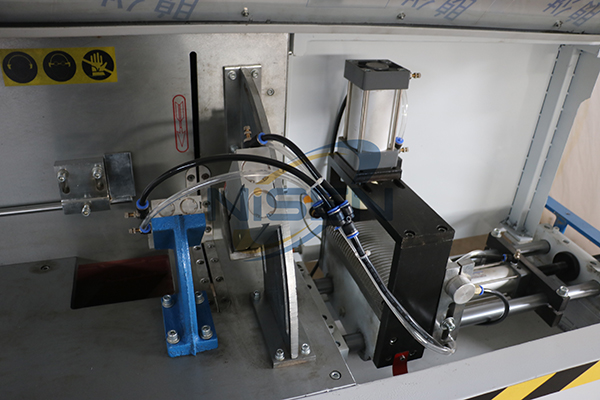

Semicircle clamping system can change the clamping angle to better fix the profile.

It can process profiles of various shapes.

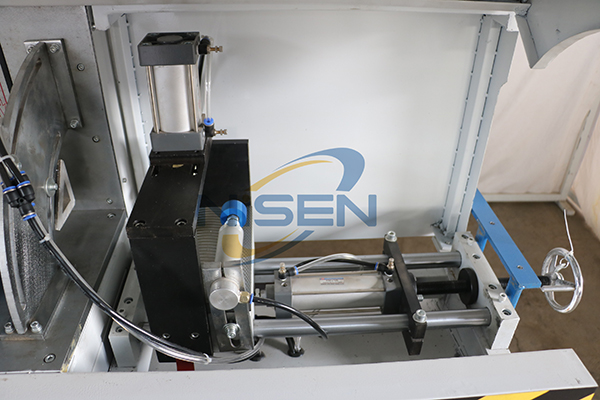

Reciprocating/single point displacement feed structure can make the machine run more smoothly and ensure the cutting accuracy.

Longer working table and feed device ensure the machine more stable when processing the long profile and ensure the cutting precision.

Packing & Delivery

All the machine packed with standard export wooden case to make sure customer will received the machines they ordered intact.

All the machines & accessories can be shipped worldwide by sea, by air or by international courier via DHL, FEDEX, UPS.

Packing Detail:

➢ Inner package: stretch film

➢ Outside package: standard export wooden cases

Delivery Detail:

➢ Usually we will arrange dispatch within 3-5 working day after receive payment.

➢ If there are big order or customized machines, it will take 10-15 working day.

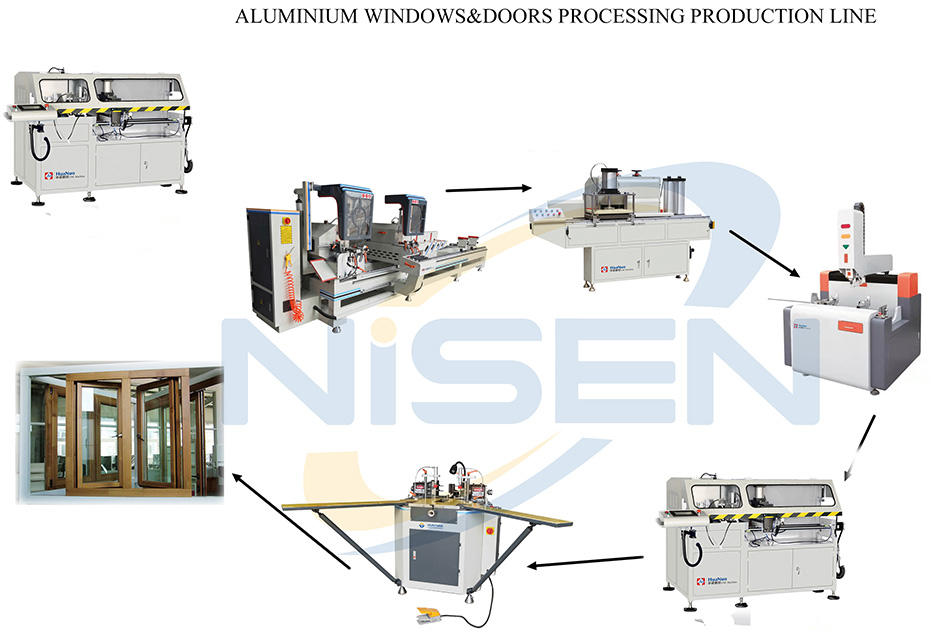

Upvc Window & Door Processing Solution

We will according to customer’s requirements (budget,plant area etc ), to provide the best solution for customers.

All project report and factory layout arrangement are available for valuable customer.

Machine Maintenance

Machine maintenance is necessary, it will helpful for your machine life, please clean all dusty after use the machine.

7.1 Check and change saw blade usually.

7.2 Check air filter device as normal.

7.3 Check air cylinder work normal or not.

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for Factory For Aluminum Profile Cutting Machine - Aluminium Corner Connector Profile Cutting Machine – Nisen, The product will supply to all over the world, such as: Portugal, Algeria, Greece, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.