| PARAMETER |

|

| INPUT VOLTAGE | 380V/50HZ |

| INPUT POWER | 1.5KW |

| MILLING CUTTER ROTATE SPEED | 2800r/MIN |

| AIR PRESSURE | 0.4~0.7MPa |

| PROFILE HEIGHT | 20 ~150MM |

| PROFILE WIDTH | 20~100MM |

| OVERALL DIMENSION | 1600*880*1650MM |

Here is some tips for your reference:

SETP-1 First give three phase connection , then connect air.

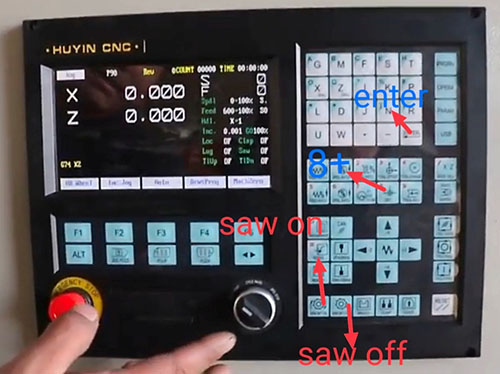

SETP-2 Press on saw and off

Check the saw blade rotation direction ; if direction is wrong ,then interchange the 2 phase wire;

SETP-3 Then press the 8 and enter, for new screen

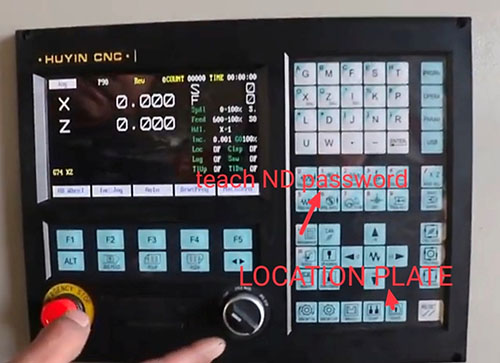

SETP-4 Then press teach and password key ( Display new screen)

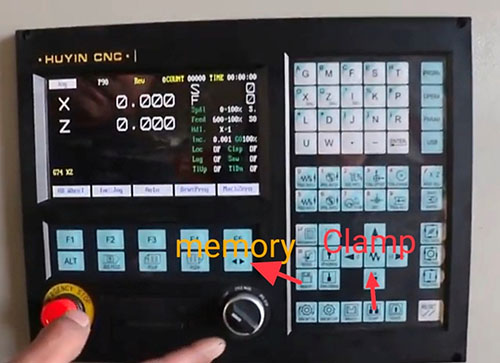

SETP-5 Put the window, then press location key, then press memory key.

SETP-6 Press clamping key, then press memory;

SETP-7 Press location key, then press memory key to keep the action;

SETP-8 Then press saw on key, after motor start, press memory,

SETP-9 Press jog feed (F3), to adjust saw speed to 100mm/s

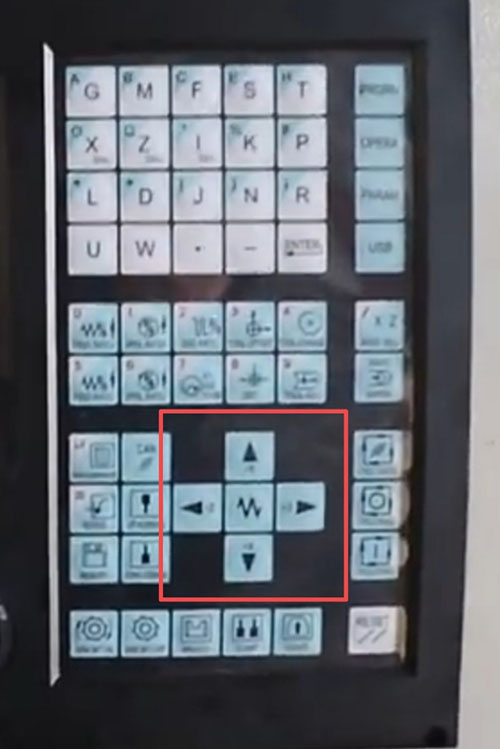

SETP-10 Then press +x or -x or +y or -y, after every step, press memory key.

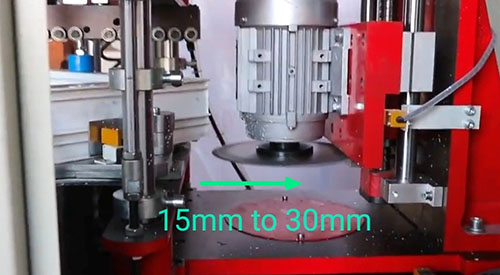

SETP-11 After finishing outside corner Z axis need move to some distance (15-30mm), then press memory key.

SETP-12 Then press saw off key, then press memory.

SETP-13 Press the broach key, finish broach coming down; then press memory key;

SETP-14 Press clamp ,let loosen, then press memory key.

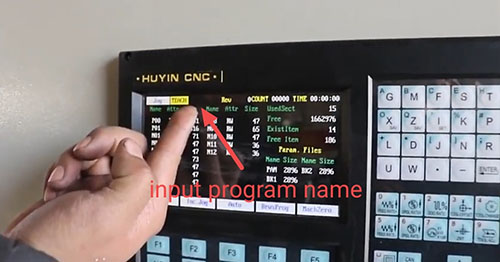

SETP-15 After finish all steps, press teach password, system enter program management interface;

INPUT PROGRAM NAME

(E.G. P03 THEN ENTER )

If there is cursor blinking after teach position in screen, it means waiting for input program's name. After input name, then will produce new program(for example: P03, press P, 0, 3 key ), then press a35 key, when scree change to picture one. it is ok.

Post time: Jun-03-2021