Plastic steel doors and Windows can be welded by plastic steel welder.

Plastic steel welding machine, is the abbreviation of plastic steel doors and Windows welding machine, refers to the machine used to weld plastic steel doors and Windows, is a complete set of plastic steel doors and Windows equipment, but also one of the most important.

Welding mode:

1, old welding

Press the positioning button, positioning plate out, after the clamp forward feed, the profile along the positioning plate to push the positioning plate, so that the end of the profile under the positioning plate, and close the positioning plate. Press the pressing button, then after the pressure clamp down, the profile pressing; Push the other profile along the front positioning plate to the lower positioning plate, and make the end of the profile tight under the positioning plate, press the press clamp button again, before the pressure clamp down, the profile pressed. Observe whether the pressure is good, if there is a problem, you can press the press clamp button again, so that the pressure clamp lift re pressing profile.

2. T-type welding

After the t-shaped welding machine head is adjusted in place, the profile cut with a V-shaped mouth is close to the rear positioning plate, and moved to the symmetrical position of the center line of the v-shaped mouth of the press clamp, press the positioning button, so that the v-shaped mouth on the profile and the 90° Angle of the positioning plate automatically fit positioning; Press the press clamp button, after the upper pressure clamp down pressing profile; Then the section with ∧ type sharp Angle is pushed down the positioning plate along the front positioning plate, so that the close contact. Press the pressing button again, the front upper pressing clamp falls, pressing the profile. Observe whether the pressure is good, if there is a problem, you can press the press button again, press the pliers lift, re-press.

Note: before pressing the button, leave the area where the pliers press.

3, automatic welding

Press the automatic welding start button after the selected heads have finished the profile pressing, then the welding machine will automatically complete the welding work.

Emergency troubleshooting during welding process

If an emergency fault occurs in any welding process, press the emergency stop button on any welding head, then the welding machine will automatically return to the initial position. After troubleshooting, be sure to turn the emergency stop button clockwise, the welding machine can work again.

4. Welding of any Angle

When welding any Angle, remove the front and rear positioning plates respectively on the right nose, and install the fan-shaped front and rear positioning plates respectively in place, adjust the required Angle according to the requirements, and then welding can be done.

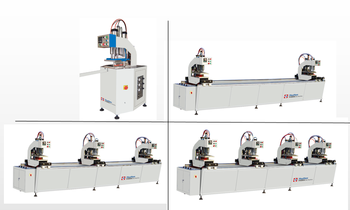

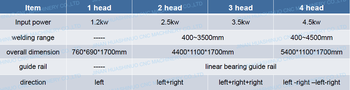

Welding machine type

Common welding machine seamless welding machine

• Parameters of the difference between

• The difference between ordinary welding machine and seamless welding machine

If weld with common welding machine and then clean the surface, there will be 3mm groove, showing the inner side,white colour, so the surface is not good. But with seamless welding, there is only very thin line on the surface.

Seamless welding machine especially used for special coloured UPVC profile.After welding, the cutters can clean up&bottom surface automatically.Then only need some manual tools to clean the outside&inner corner.seamless welding and common welding. The 2 functions can change by one switch on the machine. When use colored profiles, choose seamless function to protect the surface.When use white colour profiles, choose common welding function. In this function, the welded corner strength is higher than seamless function.

Post time: Feb-14-2022