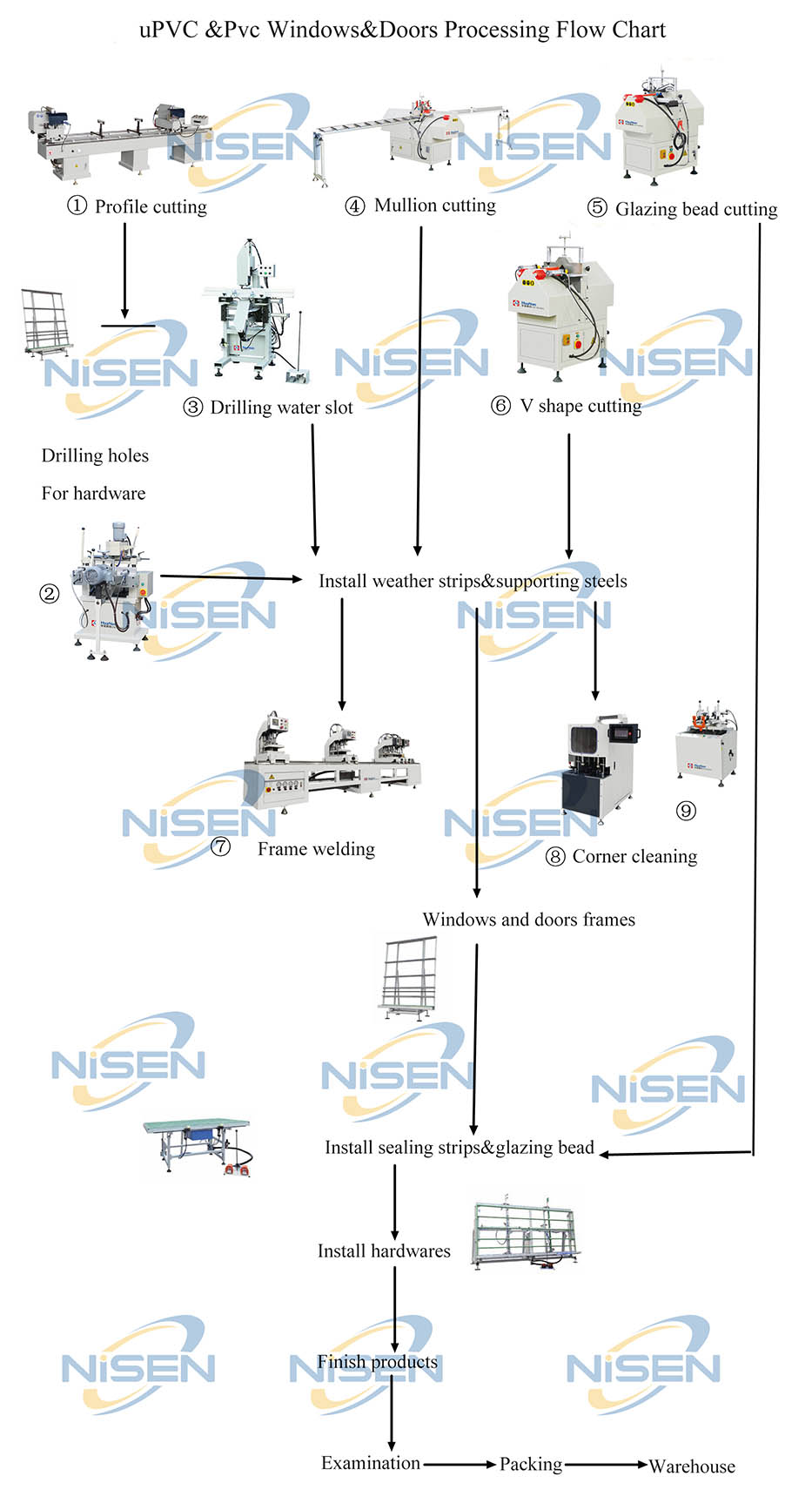

1. Door and window process drawings

First of all, please carefully review the process drawings, determine the type and quantity of windows required in accordance with the drawing style requirements, and combine the optimization of the length to make the same type and different window types to improve the utilization rate and production rate.

2. Safety process

Employees need to dress neatly, wear labor protection supplies according to work needs, concentrate on preventing dangerous accidents, and prohibit fireworks in the workshop. All personnel are prohibited from smoking.

3. Profile cutting, milling drainage holes, keyholes

A. The main profile blanking generally adopts double miter saw blanking. Leave 2.5mm~3mm at each end of the material as a margin. The welding tolerance should be controlled within 1mm, and the angle tolerance should be controlled within 0.5 degrees.

B. The frame profile should be milled with drainage holes, and the fan type should generally be milled with drainage holes and air pressure balance holes. The diameter of the drainage hole is required to be 5mm and the length is 30mm. The drainage hole should not be set in the cavity with steel lining and cannot be penetrated. Set the steel-lined cavity asphyxiation.

C. If you want to install the actuator and the door lock, you need to mill the key hole

4. Assembly of reinforced steel

When the size of the door and window structure is greater than or equal to the specified length, the inner cavity must be steel lining. In addition, the hardware assembly

Steel lining must be added to the joints of the combined doors and windows and the joints of the combined doors and windows.

And fix it. The section steel at the stress-bearing part of the cross-shaped and T-shaped connection should be just lifted after the section is melted.

Insert the butt steel at the beginning and fix it after welding.

The fasteners of the steel lining shall not be less than 3, the spacing shall not be more than 300mm, and the distance between the end of the section steel shall not be more than 100mm. The single-sided mounting holes (fixing pieces) of the whole window shall not be less than 3, the spacing shall not be greater than 500mm, and the distance from the end of the window shall not be too large

At 150mm. The T-shaped connection needs to have mounting holes at 150mm on both sides of the middle support

5. Welding

When welding, pay attention to the welding temperature 240-250 °C, the feed pressure 0.3-0.35MPA, the clamping pressure

0.4-0.6MPA, melting time 20-30 seconds, cooling time 25-30 seconds. Welding tolerance should be controlled within 2mm

6. Clear corners, install rubber strips

A. Angle cleaning is divided into manual cleaning and mechanical cleaning. After welding, the angle can be cleaned after 30 minutes of cooling.

B. Frame, fan and glass bead, install different types of rubber strip tops according to requirements. Frame, fan rubber strip’s upright part;

The length of the rubber strip should be about 1% longer to prevent the rubber strip from shrinking. There is no loosening, grooving, or middle butt joint after installation of the rubber top

7. Hardware assembly

The finished plastic-steel doors and windows are assembled by the frame and the fan through hardware. The principle of hardware assembly is:

Sufficient strength, correct position, meeting various functions and easy to replace, the hardware should be fixed in the inserted enhanced type

On the lining steel, the hardware fixing screws must be installed in full, and the installation position of the hardware must be strictly in accordance with the standard.

Row.

8. Glass installation

In the part where the glass is to be installed, put the glass block first, put the cut glass on the block, and then pass the glass

The glass bead clamps the glass firmly.

9. Finished product packaging and quality inspection

Before the doors and windows are made and leave the factory, they need to be packaged to prevent pollution. The packaging should be in the place where the doors and windows are easily contaminated, and the packaging should be one-sided without affecting the installation. The single-sided packaging tape shall be no less than 3 points and the spacing shall not be greater than 600mm. After packaging, mark the window size in a prominent position.

After the plastic doors and windows are assembled, strict quality inspections are required.

A. Appearance inspection: The surface of doors and windows should be smooth, free of bubbles and cracks, uniform in color, and welded seams should be smooth, and there should be no obvious scars, impurities and other defects;

B. Appearance size inspection: strictly control the quality of doors and windows within the allowable deviation of the national industry standard;

C. The sealing strips are equipped with uniform tops, tight joints, and no grooving phenomenon;

D. The sealing strip assembly should be firm, the gap between the corners and the butt joints should not be greater than 1mm, and they should not be on the same side.

Use two or more adhesive strips;

E. The hardware accessories are installed in the correct position, complete in quantity, and installed firmly.

Post time: Sep-06-2021