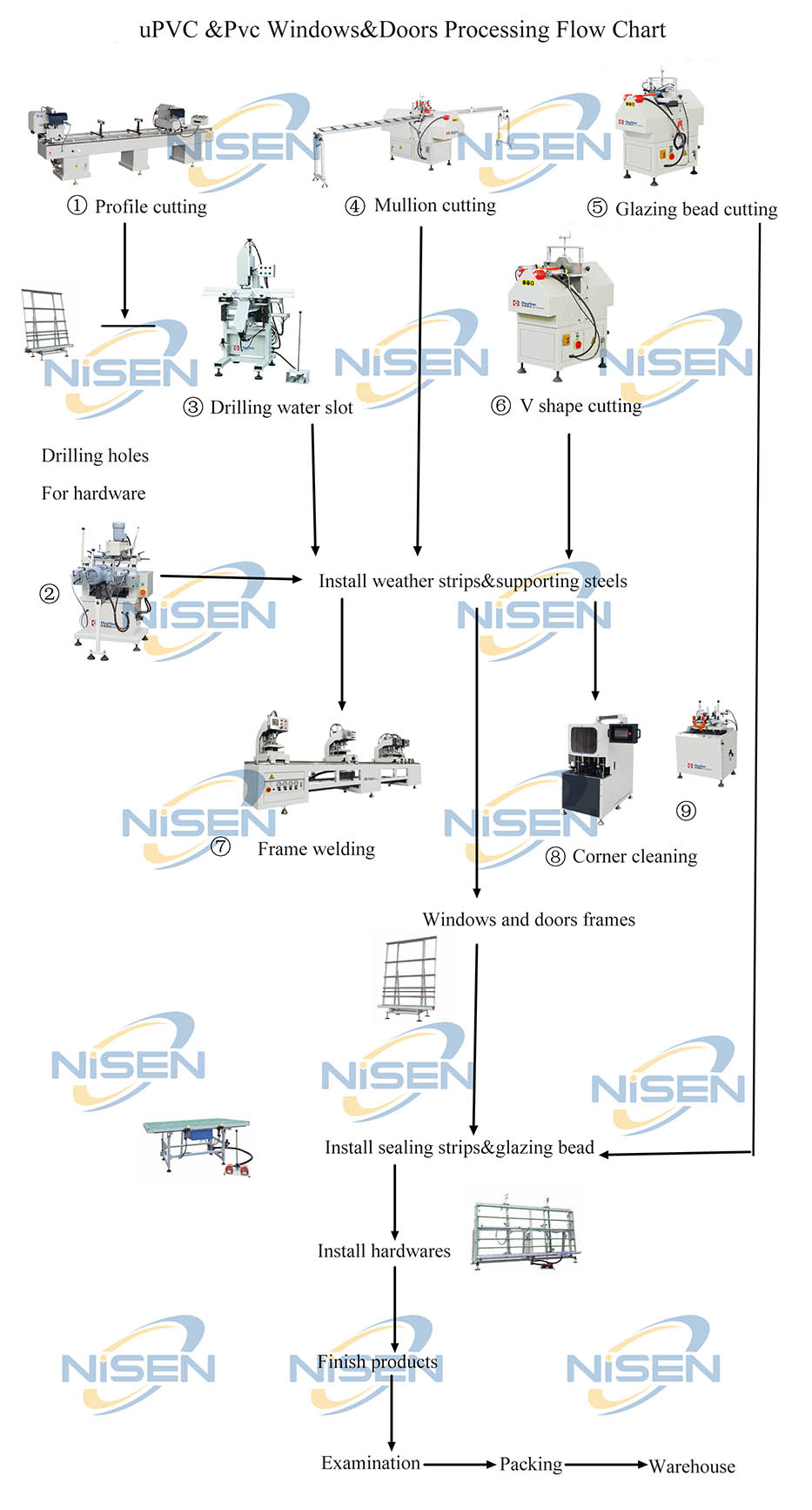

1. Production process

1. Process flow of casement doors and windows

Sawing the main profile → opening the V-shaped opening → milling the drain hole → cutting the shape steel → loading the section steel → welding → clearing the corner → hand

Moving grooves→drilling hardware holes→cutting glass bead→installing sealing strip→installing glass bead→installing hardware accessories→inspecting

→Packing→Warehousing

2. Process flow of sliding doors and windows

Sawing profile→milling drainage hole→cutting section steel→installing section steel→installing tops→welding→clearing corners→manually milling grooves

→Drilling hardware holes→cutting glass layering→installing sealing strip→installing glass layering→cutting windproof strip→drilling windproof strip→

Wind-proof strip milling grooves → wind-proof strips installed tops → installed wind-proof strips → installed buffer blocks → installed rollers → frame fan assembly → installed dense

Seal bridge→install crescent lock→inspect→pack→warehouse

2. Process development and improvement

There are many assembly processes for aluminum alloy doors and windows, and each process has an impact on product performance. According to product performance requirements

Requirement, we compare the process conditions of each process and the impact on product performance, constantly adjust the process, determine the best process parameters, and make the product meet the standard requirements.

Process formulation. The following is the process flow of several main processes.

1. Cutting the profile

Our company uses HYSJ02-3500 double angle saw for plastic and aluminum profiles. Working pressure 0.4-0.6MPa, consumption

Air capacity 100L/min, stepless speed regulation, working length 450-3500mm, use this saw to cut material, size

The tolerance is controlled within ±0.5mm.

Before using the double-angle saw to blank, first determine the blanking size according to the drawing and the blanking list. In mass production, the next step should be taken first, and after the inspection is qualified, the mass production should be put into production. During production, the size of components should be checked continuously to ensure the qualified rate of product batches.

2. Milling the sink

Our company uses HYDX-01 multifunctional milling machine for plastic and aluminum profiles. Working pressure 0.4-0.6MPa,

The air consumption is 45L/min, the milling cutter specifications are Ф4mm*100mm, Ф4mm*75mm, and the milling head speed is 2800 rpm.

Before milling the sink, be sure to know the number and location of the leaking holes. After clarifying, put the profile to be milled on the right position on the Tommy frame, and then start milling. In addition, pay attention to the location of the sink when milling the sink. When milling a fixed window of a casement window, you must determine the direction of the sink according to whether the window type is internal casement or external casement, and the specific installation method. Scrap cleaning and guide shaft lubrication should be carried out in time for each shift.

3. Open the V-shaped port

V-shaped cutting saw is used for cutting 90°V-shaped grooves of aluminum alloy profiles, suitable for material width 120 mm, length

1800 mm. Our company uses V45 type saw, working pressure 0.4-0.6MPa, gas consumption

80L/min, cutting depth ma*70, saw blade specification 300*30, saw blade speed 2800r/min, feed speed

Degree: Stepless speed regulation. First, adjust the lifting platform tightening handle according to the depth of the V port, and then shake it to the desired position.

The clamping handle also determines the horizontal positioning size according to the position of the V port.

4. Welding

This is a very important job. Our factory uses HYSH (2+2)-130-3500 aluminum alloy

Four corner welding machine for doors and windows. Through welding, we understand the main factors that affect the welding strength according to the characteristics of the profile.

The factors are the welding temperature, clamping pressure, heating time, and pressure holding time. If the welding temperature is too high, it will affect the surface after welding, and the profile will easily decompose to produce toxic gas; if it is too low, it will easily lead to false welding. The clamping force must reach a certain pressure value to make the profile section fully fit, otherwise it will affect the fusion strength of the weld. Through the anti-director test, we have determined the best heating time and pressure holding time. The pressure holding time is determined according to the first three factors, and it is only necessary to reach the appropriate time. Under different process conditions, test the fillet strength according to the standard and select the best process conditions. In this way, we determine the welding process parameters: welding temperature 240-251℃, clamping force 0.5-0.6 MPa, heating time 20-30s, holding pressure time 30-40s, under this parameter, the test fillet strength is the best. During welding, the verticality of the frame and the error of diagonal dimensions should be checked in time. If there is anything wrong, the welding machine should be adjusted in time.

5. Angular strength testing machine

Used to detect the mechanical properties of aluminum alloys and measure the fracture strength of the door and window corners, so as to better control the welding

quality.

6. Clear corner seam

In the corner cleaning, HYSQ-120-I, SYSQ-90-Ⅱ single-sided portable corner cleaning machine and HYSQ-N,

HYSQ-W inside and outside corner cleaning machine is equipped with a special air compressor to improve work efficiency and the quality of corner seam cleaning. The set

The working air pressure is 0.4-0.6MPa, the air consumption is 25L/min, 0.3m3/min, and the milling cutter speed is 18000r/min.

For the aluminum alloy doors and windows of the Welding Friends, the HYSQ-120-I type corner seam cleaning machine is used to clean the corners.

7. Glass bead cutting saw

Our company uses HYBJ-W-26 glass bead saw, working pressure 0.4-0.6MPa, air consumption

45L/min, saw blade speed 2800 rpm, processing length range 120-1800mm. Pressing in cutting glass

When striping, the blanking size of the glass bead should be controlled within ±0.5mm. The installation clearance at the corner is controlled within ±

Within 0.5mm. In addition, when cutting short bead, because the positioning size cannot be used for direct positioning and measurement, a steel ruler should be used in conjunction.

8. Assembly

When attaching rubber strips to the fixed frame and fan, we specially made special rollers. At the corners, rubber should be properly made

The leather strip is effectively embedded in the groove. The shrinkage of the rubber strip should also be considered, and a certain margin should be left in an appropriate amount.

When installing the aluminum slide bar, you should measure the size first, then load the aluminum bar, and then use a nylon hammer to gently knock the aluminum slide bar into the groove evenly.

When installing the glass bead, install it in the order of short first and then long. In order to prevent breaking the glass and causing cracks at the corners of the frame and fan, apply moderate force when striking.

When installing the hardware, determine the location and number of the hardware according to the standard, and do not miss the installation. Finally, it should be

Check it again.

3. Process supervision

1. According to the production situation of the product, our company has formulated the product process and the operating procedures of the handicraft, according to the standard

Standardized preparation requirements, process documents are complete, can guide product production and testing.

2. The reliability of the equipment and the rationality of the process

At present, the door and window production assembly line is relatively advanced in China. Our company has purchased a complete set of door and window assembly lines.

The level is reliable, and the process developed according to this set of equipment can fully guide production.

3. Testing and equipment

According to JGJ/T3018-94, the following items are tested.

3.1 Angular strength, angular strength testing machine.

3.2 Reinforced steel, caliper detection.

3.3 Detection of switching force and spring scale.

3.4 Size, tape measure detection.

3.5 Assembly gap, feeler gauge.

Post time: Oct-11-2021