Low price for Upvc Cnc Corner Cleaner - Auto End Milling Machine For PVC Window Processing – Nisen

Low price for Upvc Cnc Corner Cleaner - Auto End Milling Machine For PVC Window Processing – Nisen Detail:

Feature of upvc window machine

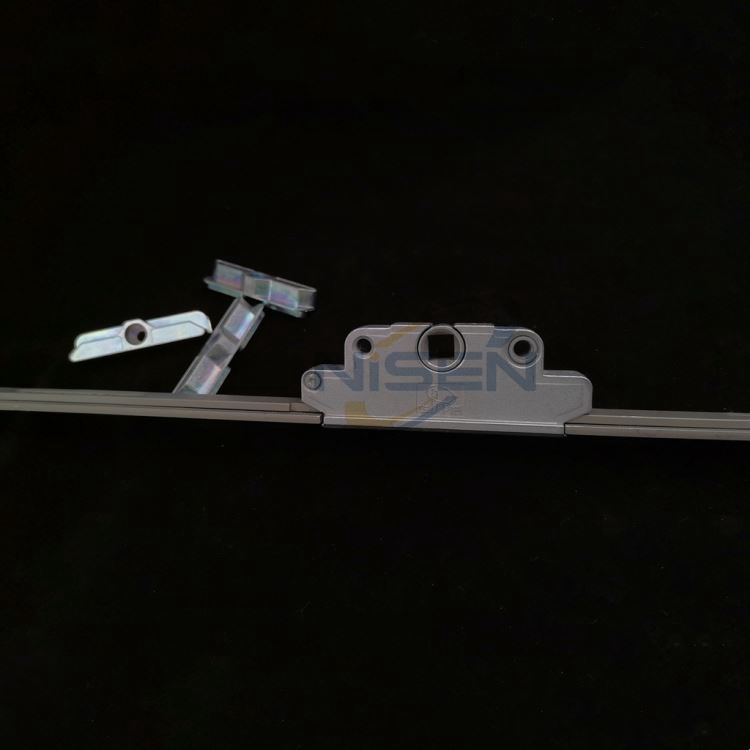

➢ Used for processing aluminum & upvc profile end, step face and slot etc.

➢ Super precision main shaft insures accurate and steady processing.

➢ Automatic feeding.

➢ Large worktable for milling multi-piece profiles at same time.

➢ Convenient tool setting is due to adjustable worktable.

➢ Various angle mullion milling for arch window or other special shape window.

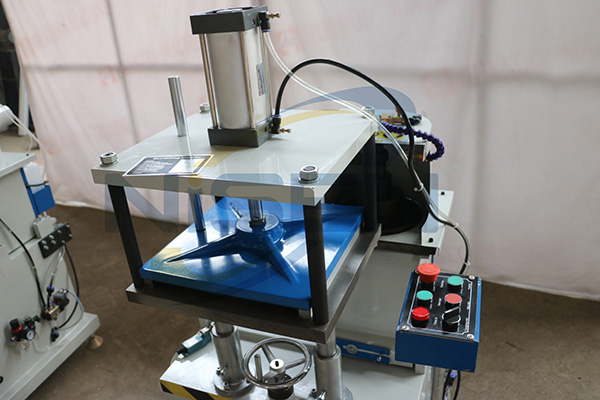

➢ Safety covers on the milling cutter.

➢ Hand wheel for different height adjustment.

➢ Cutter easily changing for various profile.

➢ Vertical clamping ensure stable positioning.

Technical Specifications

| Power supply |

380V,50-60Hz, Three Phase |

| Input power |

1.5kw |

| Motor rotary speed |

2800r/min |

| Air pressure |

0.6~0.8Mpa |

| Air comsumption |

30L/min |

| Main shaft diamter |

Φ32mm |

| Cutter adjustment |

0~80mm |

| Milling cutter height |

70mm |

| Cutter diameter |

(φ200~110)*φ32mm |

| Feeding journey of worktable |

0~320mm |

| Overall dimension |

850*740*1500(L*W*H) |

Standard Accessory

| Cutters | Customized according to requirements |

| Air gun | 1pcs |

| Complete tooling | 1set |

| Certificate | 1pcs |

| Operation manual | 1pcs |

Product Details

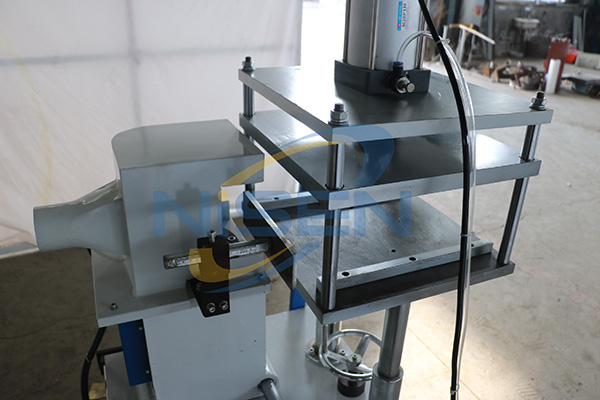

Hand wheel of end milling machine for different height adjustment.

Vertical clamping device ensure stable positioning. And it can hold more than 2 profiles with high working efficiency.

Packing & Delivery

All the machine packed with standard export wooden case to make sure customer will received the machines they ordered intact.

All the machines & accessories can be shipped worldwide by sea, by air or by international courier via DHL, FEDEX, UPS.

Packing Detail:

➢ Inner package: stretch film

➢ Outside package: standard export wooden cases

Delivery Detail:

➢ Usually we will arrange dispatch within 3-5 working day after receive payment.

➢ If there are big order or customized machines, it will take 10-15 working day.

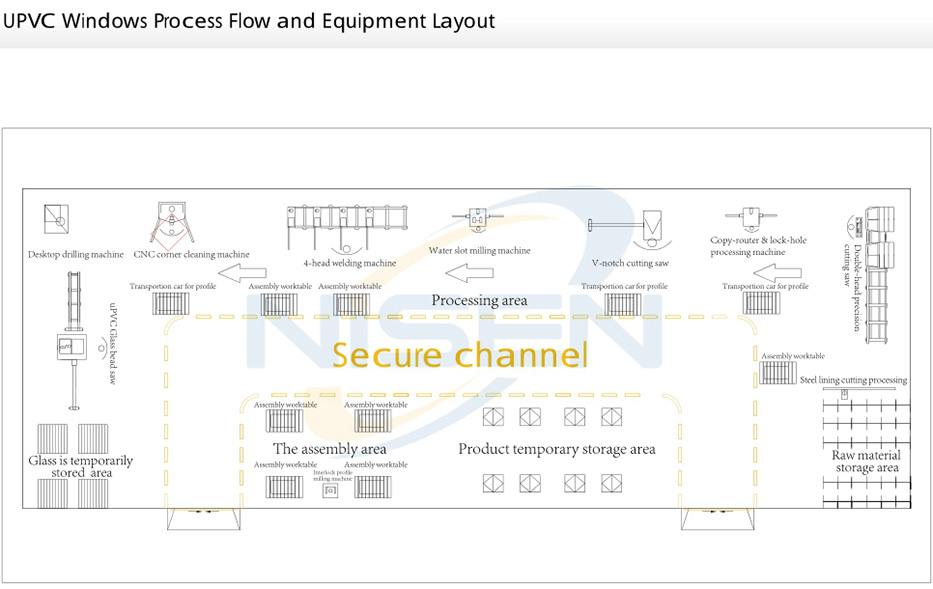

Upvc Window & Door Processing Solution

We will according to customer’s requirements (budget,plant area etc ) , to provide the best solution for customers.

All project report and factory layout arrangement are available for valuable customer.

Machine Maintenance

Machine maintenance is necessary, it will helpful for your machine life, please clean all dusty after use the machine.

7.1 Check the milling cutters, keep it sharply and clean;

7.2 Add lubricating oil on the guide rail.

Product detail pictures:

Related Product Guide:

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for Low price for Upvc Cnc Corner Cleaner - Auto End Milling Machine For PVC Window Processing – Nisen, The product will supply to all over the world, such as: Ottawa, Costa rica, India, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.